What is a Zeta Power™ System ?

- A high voltage capacitance based water treatment system that changes the physical properties of colloidal particles

- A strong electro-dispersant, and electro-bio-dispersant

- An electronic deposit control system

- An industrial fluid treatment system

What does a Zeta Power™ do ?

- Prevents the formation of mineral deposits

- Prevents the formation of biofilm

- Eliminates existing biofilm

- Prevents microbially induced corrosion

- Prevents RO membrane fouling

- Prevents coolant biodegradation

- Maintains clean heat transfer

- Enhances chemical efficiency

- Improves flocculation

- Replaces salt based water softeners

What a Zeta Power™ is not ?

- Zeta Power™ is not a biocide

- Zeta Power™ is not a filter

- Zeta Power™ is not a softener

- Zeta Power™ is not a corrosion inhibitor

- Zeta Power™ is not a descaler*

Biofouling : Why is it a problem?

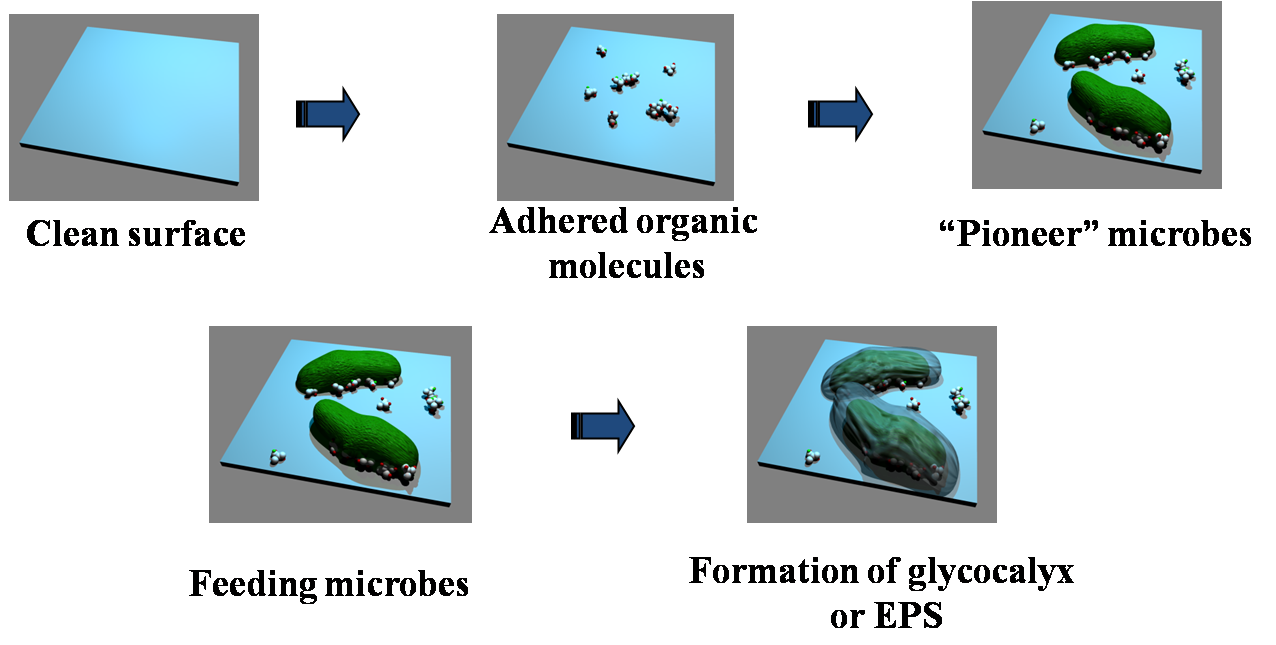

- How biofilms develop

- Resistance of bacteria within a biofilm

- Why are biocide treatment methods inefficient

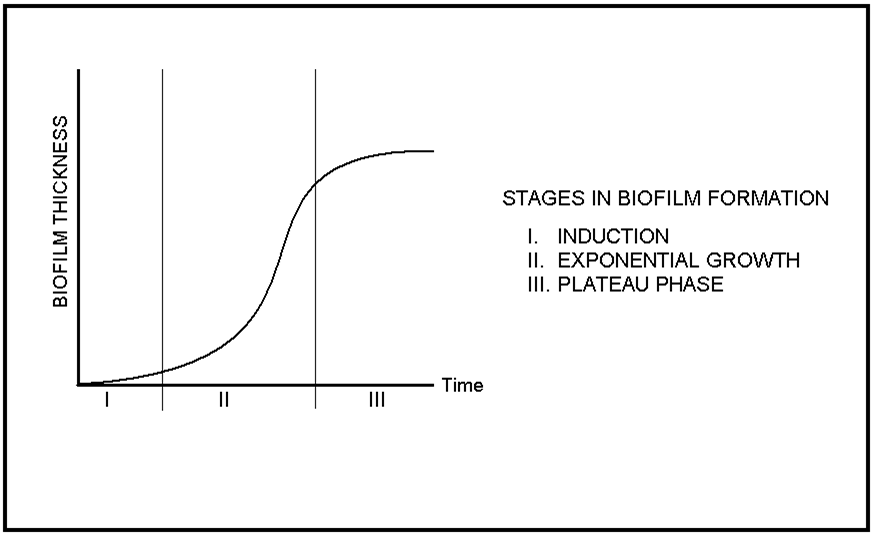

Biofouling as a Three-Phase Process

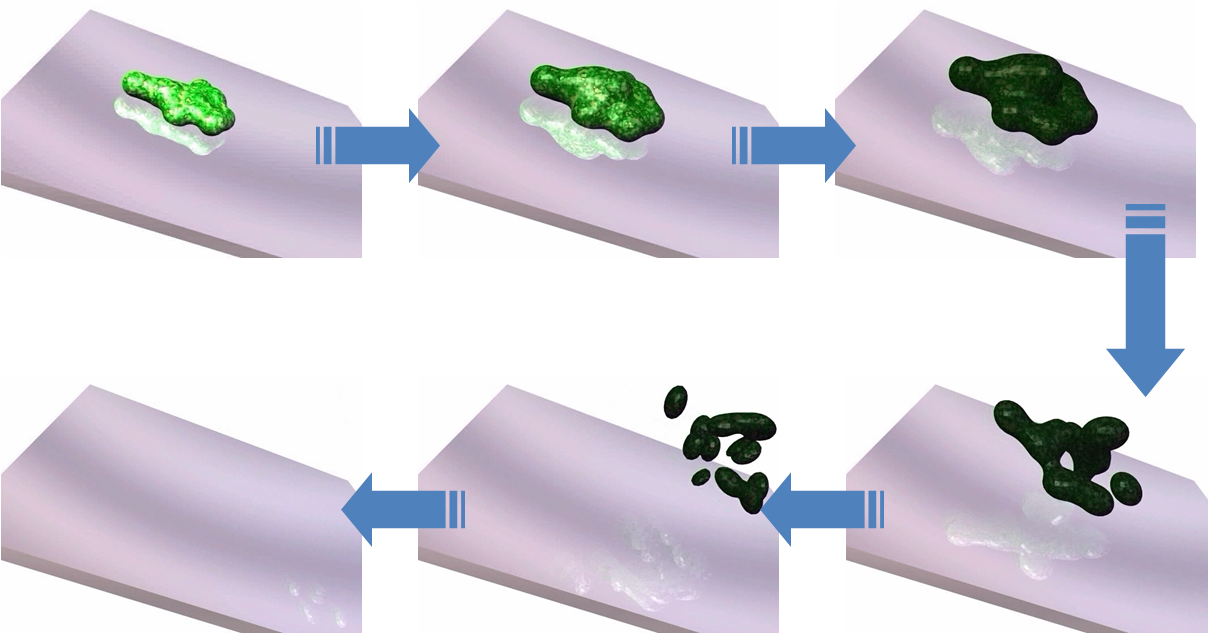

Biofilm Development in Water Systems

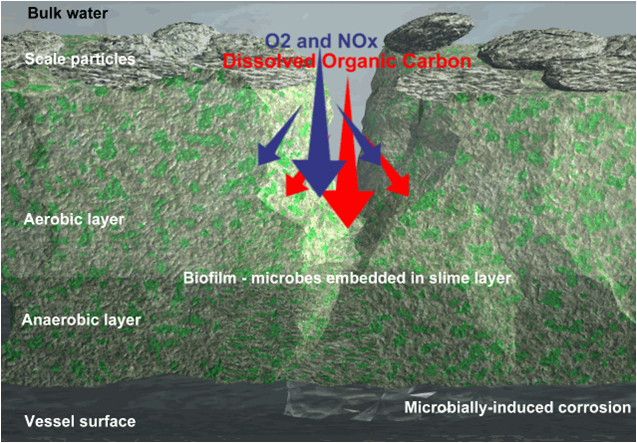

Fully Developed Biofilm

Problems with current treatment

- Biocides are designed to“kill”bacteria, not to remove, or prevent formation of biofilms

- Bacteria growth takes place within biofilms

- Bacteria can go into“dormant”status when in a biofilm

- Bacteria in biofilms can be as much as 2 to 500x more resistant to biocides

- Insufficient dosages of biocides can result in bacteria with higher tolerance

- SUMMARY : Current methods focus on the symptoms (bacteria) and not the cause of the problem (biofilm)

How does Zeta Power™ control biofilm

- Reducing surface tension of water allows existing biofilms to superhydrate and be easily removed by turbulence of fluid.

- The Zeta Power™ causes hydration, swelling, and loosening of biological deposits leading to the removal of fouling from wetted surfaces.

- By keeping bacteria from attaching to a surface it prevents them from reproducing

- The combined effect of bacteria dispersion and biofilm disintegration makes the Zeta Power™ a superior biofilm control system

Scale Control in Industrial Fluid Systems

- Sources and Causes for Scaling

- Hardness in the water

- Specialty chemicals used in metal finishing operations (phosphatizing, anodizing, etc)

- Physical/Chemical conditions of the fluid: high temperature, high pH, increased concentration of salts due to evaporation.

How does Zeta Power™ control scale

- By increasing Zeta Potential of colloidal particles and wetted surfaces a strong dispersion is created which prevents particles from forming scale deposits.

- By eliminating biofilm, it removes the primary“glue”that holds scale in place, causing scale in many situations to fall off.

Scale Control

Why not to offer the Zeta Power™ for Descaling?

- Too many variables make it impossible to determine how much scale and how soon will it fall off

- Scale removal is not as predictable as biofilm removal

- Always warn the customer of the potential of scale falling off